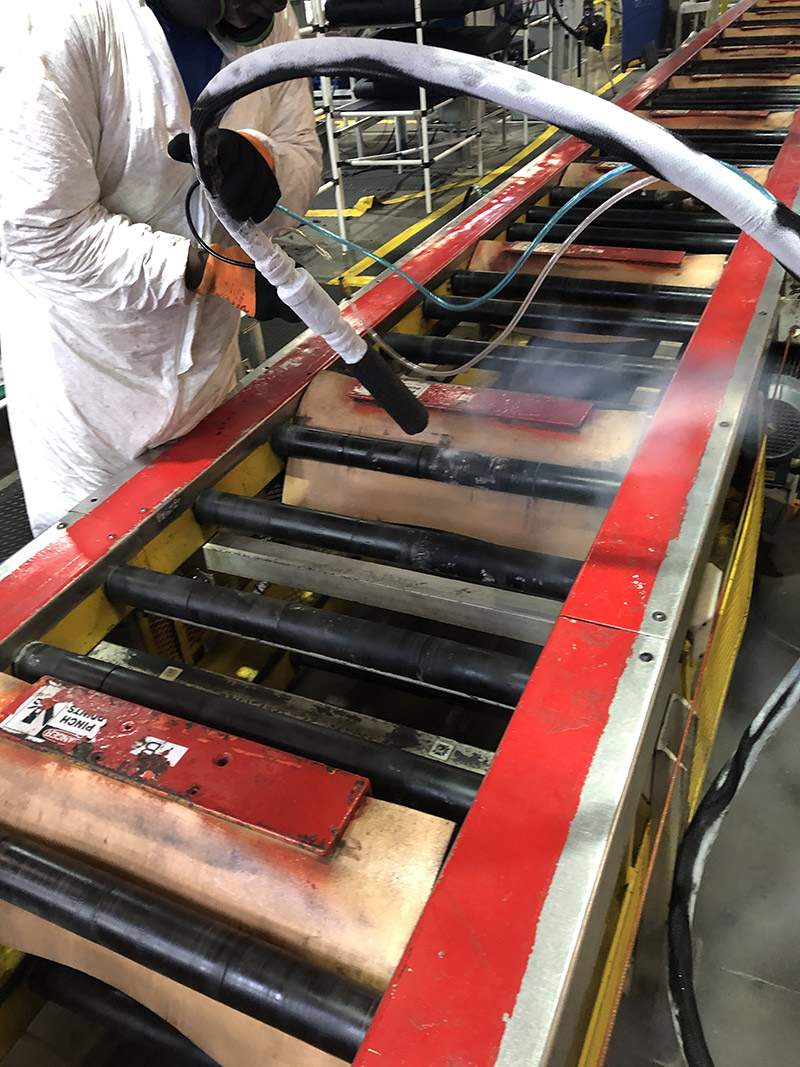

Dry Ice Cleaning

What is Dry Ice Cleaning?

Dry Ice Cleaning is a unique industrial cleaning method that uses specialized equipment to mix dry ice (solid carbon dioxide) pellets with compressed air. The compressed air accelerates the dry ice pellets through a blast hose. The pellets exit the hose near supersonic speeds and impact the surface. Upon impact the dry ice pellets convert to a gas and the rapid gas expansion of CO2 facilitates the removal of the surface contaminates.

Dry ice cleaning is non-abrasive, non- flammable, non-conductive, environmentally friendly, and approved by the EPA, FDA, and USDA.

Removal

- Adhesives

- Resins

- Biofilms

- Greases

- Oils

- Production Residues

- Release Agents

- Asphalt Tar

- Contaminants

- Mold

Benefits

- Eliminates the need to shut down production for cleaning

- Reduces cleaning costs

- Reduces labor costs

- Replaces manual scrubbing and the use of chemical agents

- Reduces waste disposal and cost (no secondary waste)

- Clean in place without disassembly and without producing fire or electrical hazards

- Eliminates surface degradation (non -abrasive)

- Extends equipment life

Applications

- Manufacturing: Automotive Plants, Medical Device Manufacturing, Aerospace, Machining Equipment, Printing Presses, Industrial Ovens, Plastic Molds, Foundry Molds, Semiconductors, Resin Removal, Tank Cleaning

- Electrical: AC/DC Motors, Electrical Boxes, Circuit Breakers

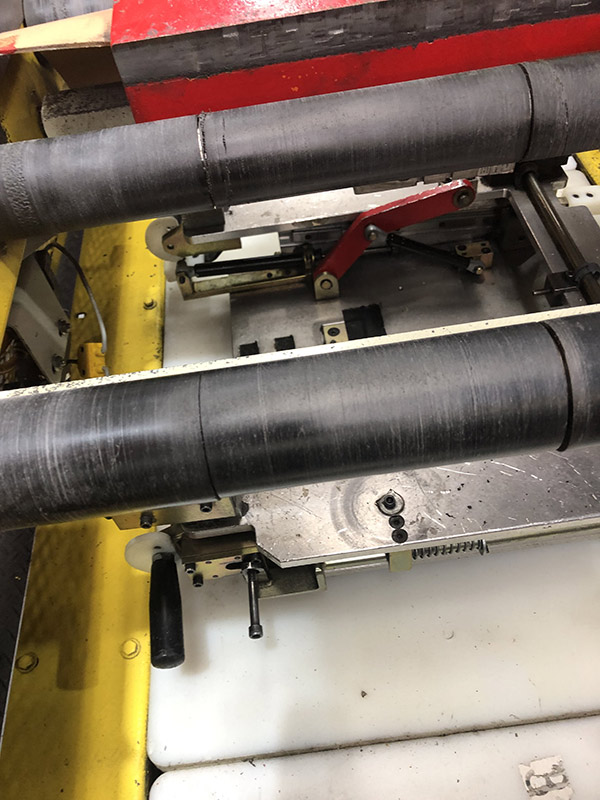

- Facility Equipment: Conveyors, Conveyor Chains, Cooling Fans, Forklifts, Fleet Vehicles, Pipes and Hoses, General Equipment

- Real Estate: Parking Garages, Graffiti Removal, Escalators, Stairwells, Ceilings, Walls, Building Exteriors, Gum Pollution

- Restoration: Fire Restoration, Mold Remediation, Historic Restoration, Boat Hulls

- Power Generation: Transformer, Switch Gear, Bushings, Turbine, Field Frame, Armature, Rotor, Substation Isolator

Videos

See Dry Ice Cleaning in action